The seemingly endless stream of municipal waste that communities struggle to manage holds the untapped potential to power homes and fuel a more sustainable future. The development of advanced organics recovery and renewable energy facilities represents a significant advancement in the municipal waste management sector. This review will explore the evolution of this approach, its key technological components, performance metrics, and the impact it has on creating a circular economy. The purpose of this review is to provide a thorough understanding of the technology, its current capabilities as demonstrated by the Ulster County model, and its potential for future development.

The Ulster County Initiative: A New Paradigm in Waste Management

Ulster County, New York, has initiated a significant strategic shift, moving away from its long-standing reliance on traditional landfilling. This transition is embodied in a new public-private partnership aimed at constructing a state-of-the-art organics recovery facility. Managed by the Ulster County Resource Recovery Agency, this project partners with a specialized consortium led by Global NRG Advisory to transform the local waste stream into a valuable resource. The decision to pursue this path marks a departure from conventional disposal methods, positioning the county as a leader in sustainable waste management.

This initiative directly confronts pressing regional challenges, including diminishing landfill capacity, escalating disposal costs, and ambitious state-level climate objectives. By choosing to develop a facility that recovers organic matter and generates renewable energy, Ulster County is proactively addressing these issues rather than exporting its waste problem. This approach not only offers an economically viable alternative to landfilling but also aligns with New York’s goals to reduce greenhouse gas emissions, making it a highly relevant and forward-thinking solution.

Core Technologies and Processes of the Facility

Advanced Material Separation and Recovery

The facility’s process begins with a sophisticated material separation system, a critical first step in maximizing resource recovery. Household waste is subjected to an advanced sorting mechanism designed to efficiently segregate the organic fraction from recyclables and residual waste. This technology, provided by Van Dyk Recycling Solutions, ensures that a high percentage of usable organic material is captured for subsequent treatment. The precision of this initial stage is fundamental to the overall efficiency of the plant, as it dictates the quality and quantity of feedstock available for energy production.

Anaerobic Digestion for Renewable Natural Gas

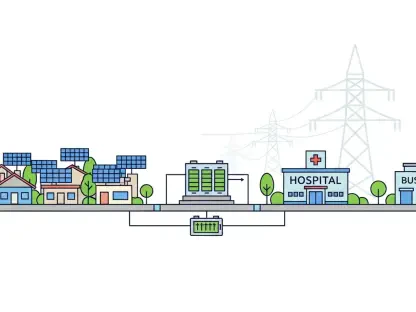

Once separated, the organic material is transferred to an anaerobic digestion system, the core of the facility’s energy-generation process. Inside a controlled, oxygen-free environment, microorganisms break down the organic matter, producing biogas. This raw biogas is then upgraded into renewable natural gas (RNG), a clean-burning fuel that can be injected into the existing natural gas grid. This conversion, managed with equipment from PlanET Biogas, not only creates a sustainable energy source but also produces nutrient-rich digestate, a byproduct that can be used as a soil amendment, further closing the loop in a circular economy.

Current Project Status and Development Timeline

The project is currently advancing through the final stages of contract negotiation between the Ulster County Resource Recovery Agency and the selected consortium. This phase is crucial for finalizing the operational and financial frameworks that will govern the long-term partnership. Upon the successful conclusion of these negotiations, the initiative will move into the detailed design and engineering phase, where the facility’s blueprints will be finalized.

Following the design stage, the project timeline includes a period for public consultation and the securing of all necessary regulatory permits. This transparent process is designed to ensure community buy-in and compliance with environmental standards. Construction, managed by ARCO/Murray, is scheduled to begin thereafter, with the facility expected to become operational within a few years, marking a major milestone in the region’s waste management history.

A Replicable Model for National Waste Management

The Ulster County facility is positioned to become a pioneering model for other municipalities across New York and the United States. Its real-world application of integrated waste recovery and energy production technologies provides a tangible blueprint for communities facing similar challenges with landfills and disposal costs. By demonstrating a viable, self-sustaining alternative, this project offers a clear path for others to follow.

The initiative’s potential extends beyond its local impact, offering a scalable framework for transforming how communities nationwide perceive and manage their waste streams. As environmental regulations become more stringent and public demand for sustainable solutions grows, the success of this model could catalyze a broader shift toward a circular economy. This would empower other regions to meet ambitious environmental targets while creating economic value from materials previously considered worthless.

Anticipated Challenges and Mitigation Strategies

The implementation of such a technologically advanced facility is not without its challenges. Technical hurdles in integrating various complex systems, navigating the intricate public and regulatory approval processes, and managing the dynamics of a long-term public-private partnership are all potential obstacles. Ensuring seamless operation and meeting performance projections will require meticulous planning and execution from all involved parties.

However, the project is structured to mitigate these risks through the expertise of its specialized consortium. Each partner brings proven experience in their respective fields: Econward Tech in waste treatment, PlanET Biogas in digestion, Van Dyk in sorting, and ARCO/Murray in construction. This collaborative approach distributes risk and leverages deep industry knowledge to overcome technical and logistical limitations, providing a robust framework for successful project delivery.

Future Outlook and Projected Community Impact

The long-term outlook for this waste-to-energy model is exceptionally promising, with the potential to significantly reduce Ulster County’s environmental footprint. By diverting 60-70% of waste from landfills, the facility is projected to dramatically cut methane emissions, a potent greenhouse gas. This reduction will contribute directly to meeting state climate goals while also diminishing local pollution and odors associated with traditional waste disposal.

Beyond its environmental benefits, the project is expected to deliver substantial economic advantages to the community. The creation of renewable natural gas reduces reliance on fossil fuels, while the on-site treatment of waste lessens the financial and environmental costs of long-distance hauling. Over time, these efficiencies, combined with improved local air and water quality, will foster a healthier and more sustainable economic environment for the residents of Ulster County.

Conclusion: Assessing the Future of Waste to Energy

The Ulster County model presented an innovative approach to waste management, successfully reframing municipal waste as a valuable resource rather than a liability. The facility’s integration of advanced sorting and anaerobic digestion technologies established a new standard for resource recovery and renewable energy production.

Ultimately, the initiative demonstrated the significant potential of public-private partnerships to drive environmental progress. The project’s successful implementation provided a powerful testament to the technology’s current state and affirmed its transformative impact on the waste management industry, offering a clear and replicable blueprint for widespread adoption.