The same rendered fats and oils left over from processing chicken for dinner tables across the country are now being refined into a powerful, sustainable fuel capable of lifting commercial airliners into the stratosphere. This innovative leap forward represents a critical turning point for the aviation industry, which has long grappled with its significant environmental impact. United Airlines is at the forefront of this movement, transforming agricultural byproducts into a viable energy source to help decarbonize its fleet and chart a course toward a greener future for air travel.

From the Fryer to the Fuel Tank: Can Dinner Leftovers Power Your Next Flight

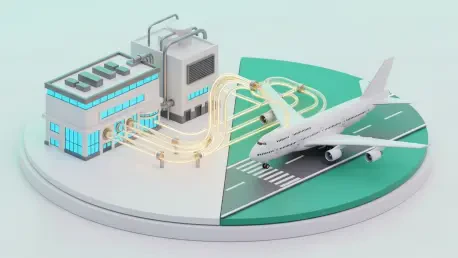

The core of this initiative is Sustainable Aviation Fuel (SAF), a classification of biofuels engineered to power aircraft with a substantially lower carbon footprint than traditional kerosene-based jet fuel. The feedstocks for this particular fuel are not purpose-grown crops but rather the residual materials from the food industry. This includes poultry fat, beef tallow, and even used cooking oil collected from restaurants, creating a direct link between the kitchen and the cockpit. By repurposing these materials, the process adds value to what would otherwise be considered waste.

However, converting these fats into high-grade jet fuel is a complex chemical process. The raw materials, particularly poultry fat, contain impurities that must be carefully removed and managed. As a result, it cannot be processed in isolation and must be blended with other fats and oils to create a stable and effective final product. This advanced refining method ensures the SAF meets the stringent safety and performance standards required for modern jet engines, making it a “drop-in” fuel that can be used without any aircraft modifications.

The Urgent Push for Greener Skies: Why Aviation’s Carbon Footprint Matters

The aviation sector is under immense pressure to address its environmental responsibilities. As a whole, the industry contributes approximately 3% of all global carbon emissions, a figure that is projected to grow as other industries successfully reduce their own pollution. For an airline like United, the challenge is particularly acute, as a staggering 98% of its total carbon output comes directly from the consumption of jet fuel. Without a viable alternative, meaningful emissions reductions are nearly impossible.

In response, United has established some of the most ambitious climate goals in the industry, aiming to achieve net-zero carbon emissions by 2050. A key pillar of this strategy involves halving its carbon pollution per passenger seat by 2035 compared to 2019 levels. SAF is expected to play a crucial role, accounting for roughly 17% of the airline’s planned path toward its net-zero target. This makes the development and scaling of waste-derived fuels not just an environmental initiative but a core business imperative.

An Unlikely Partnership: How the Poultry and Airline Industries Forged a Sustainable Alliance

At the heart of this fuel revolution is a strategic collaboration between United Airlines and Darling Ingredients, a global leader in processing animal byproducts. Through its joint venture with Valero, known as Diamond Green Diesel, Darling has become a pivotal player in the renewable energy landscape. Since late 2024, its facilities have been producing not only renewable diesel but also SAF, directly supplying the aviation industry with a lower-emission alternative.

This partnership exemplifies a powerful synergy between two seemingly unrelated sectors. Darling Ingredients processes nearly 1.5 million tonnes of low-emission raw materials annually, generating approximately 1.2 billion gallons of renewable fuels. For the poultry and broader food industries, this provides a sustainable and economically beneficial solution for managing waste. For United, it secures a vital supply of the fuel needed to advance its decarbonization efforts, creating a mutually beneficial relationship grounded in shared sustainability goals.

The Expert Viewpoint: Why Using Waste Is a Win-Win in the Biofuel Debate

One of the most significant advantages of this approach is that it effectively sidesteps the contentious “food versus fuel” debate that has long plagued the biofuel industry. Because the SAF is produced entirely from byproducts of food production, it does not compete for land or resources that could be used to grow food for human consumption. This distinction is critical, as it allows for the expansion of biofuel production without creating unintended consequences for global food security.

Experts from both United and Darling have emphasized that this model represents a win-win scenario. It creates a circular flow of resources where waste is not merely disposed of but is repurposed into a high-value product. This not only reduces landfill burdens for the agricultural sector but also provides the aviation industry with a scalable and ethically sound pathway to reduce its carbon intensity. Furthermore, representatives from both companies have indicated that the potential for this technology is far from exhausted, signaling significant room for future growth and innovation.

A Blueprint for the Future: Building a Circular Economy Across Industries

This collaboration serves as a powerful blueprint for how a circular economy can be built across different sectors. By creating a closed-loop system where one industry’s waste becomes another’s resource, the model demonstrates a practical and effective way to achieve integrated sustainability. The success of this venture is not just about technology; it is fundamentally dependent on strong cooperation among all stakeholders, including agricultural partners, waste processors, fuel producers, and airlines.

The initiative between United and Darling Ingredients ultimately demonstrated that substantial environmental progress was possible when industries looked beyond their traditional boundaries to find innovative solutions. The partnership established a viable framework for turning waste into a resource on a commercial scale, proving that cross-sector collaboration was the key to unlocking new possibilities in the global push for decarbonization. This successful alliance provided a tangible example of how shared responsibility and creative thinking could pave the way toward a more sustainable future for industries worldwide.