In an industry where consistency is paramount, Coal India Limited is spearheading a technological revolution to tackle the age-old challenge of variable coal quality. This initiative marks a strategic pivot toward automated quality control, driven by a clear objective to enhance transparency and fortify consumer confidence through verifiable, data-driven processes. The trends, technologies, and tangible results of this shift are setting a new standard for quality assurance in the sector.

The Rise of Automated Systems in Coal Quality Assessment

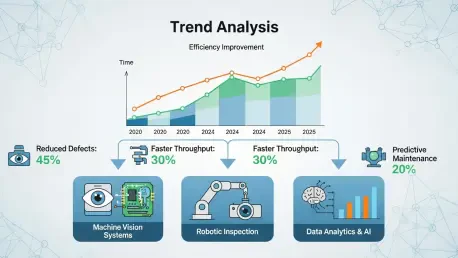

Data-Driven Momentum: Adoption and Growth Metrics

The adoption of automated systems is no longer a pilot program but a large-scale operational reality. Out of 375 million tons of coal dispatched by rail through December of the current fiscal year, nearly half was processed using advanced automated silo-based systems. This substantial volume underscores a decisive move away from manual methods toward mechanized, data-centric operations that promise greater accuracy and reliability.

This technological transition has yielded demonstrably positive results. CIL’s overall grade conformity has improved, climbing to 85% this fiscal year from 82% during the same period last year. Such a measurable increase serves as powerful evidence that automation directly correlates with higher quality consistency, validating the company’s investment in these systems.

Looking ahead, the momentum is set to accelerate. The company has established an ambitious target to increase its automated, mechanized loading capacity to approximately 80% in the current fiscal year. This expansion will be achieved by commissioning new connectivity projects, signaling a long-term commitment to integrating technology across the entire supply chain.

Real-World Implementation: CIL’s Strategic Shift

At the heart of this transformation are silo-based mechanized loading systems integrated with Auto Mechanical Samplers. CIL is actively prioritizing this infrastructure to ensure a higher degree of consistency in the final product delivered to consumers. This technology-driven process is specifically designed to circumvent human interference, thereby mitigating long-standing consumer concerns about the subjectivity of quality assessment.

To further bolster impartiality, the system operates within a framework governed by Fuel Supply Agreements, which empower consumers with oversight. Customers can select from a panel of 11 independent Third-Party Sampling Agencies (TPSAs) to conduct sampling and analysis. This mechanism ensures that the quality assessment process is not only automated but also independently verified, fostering a transparent and trustworthy supplier-consumer relationship.

Industry Insights on Modernizing Quality Control

Industry leaders and CIL management widely agree that automation is a critical instrument for instilling transparency and impartiality into the quality assessment process. By replacing manual sampling with mechanized, repeatable procedures, the system removes potential biases and creates a verifiable record of coal quality at the point of dispatch.

This strategic pivot toward automated systems is a direct and calculated response to persistent consumer demands for more reliable and consistent coal supplies. In a competitive energy market, predictable fuel quality is essential for optimizing operational efficiency and managing costs, making CIL’s initiative a vital step in meeting market expectations and strengthening its competitive position.

Ultimately, the new systems are engineered to foster greater trust and accountability between supplier and consumer. By minimizing manual intervention, the process inherently reinforces the terms outlined in Fuel Supply Agreements. This alignment ensures that both parties operate from a shared, data-backed understanding of product quality, reducing disputes and strengthening commercial partnerships.

The Future of Coal Quality: Projections and Challenges

CIL is continuing its technological advancement by introducing online analysis systems at two of its subsidiaries. This next-generation integration will enable real-time quality assessment, providing immediate feedback that can be used to make swift operational adjustments and further refine the consistency of coal dispatched to consumers.

A primary benefit of this ongoing trend is the expected continued improvement in grade conformity and enhanced operational efficiency across the entire supply chain. Faster, more accurate quality data allows for better logistics planning, optimized inventory management, and more precise alignment with customer specifications, creating value for both CIL and its clients.

Despite these significant technological strides, the high heterogeneity of Indian coal remains a formidable inherent challenge. The quality of coal can vary substantially even within the same seam, a natural inconsistency that technology can manage but not eliminate entirely. This geological reality necessitates a robust and adaptable quality control framework. The overarching trend clearly indicates CIL’s unwavering commitment to leveraging technology as its primary tool for managing and overcoming these natural variables, turning a persistent challenge into a manageable aspect of its operations.

Conclusion: A Commitment to Technological Advancement

CIL’s focused investment in automated sampling and mechanized loading has marked a significant and defining trend in industrial quality control. This strategic direction not only addressed immediate consumer needs for greater reliability but also established a new, higher benchmark for quality assurance across the sector.

The measurable success of this initiative, evidenced by a steady rise in grade conformity, has validated the core principle that replacing manual intervention with technology-driven processes yields superior and more consistent outcomes. This data-backed achievement reinforces the effectiveness of the automated approach.

Ultimately, this pivot toward automation has done more than solve a logistical problem; it has repositioned technology as the cornerstone of CIL’s commitment to quality. The initiative demonstrated a forward-thinking strategy that prioritizes transparency, accountability, and customer satisfaction, fundamentally reshaping the landscape of coal quality management for years to come.