A transformative era for Thailand’s aviation industry has officially begun as the nation implements a landmark policy mandating the blending of Sustainable Aviation Fuel (SAF) with conventional jet fuel, a regulation that took effect on January 1st. This decisive move, orchestrated by the Department of Energy Business, is not merely a procedural update but a strategic realignment designed to propel the country toward its ambitious carbon neutrality and net-zero emissions targets. By establishing this new framework, Thailand positions itself as a key player in the global movement for greener skies, joining a growing list of nations committed to mitigating the environmental impact of air travel. The policy directly reflects international precedents, such as the European Union’s own blending mandates, and reinforces the objectives set forth by the International Civil Aviation Organisation (ICAO), which advocates for the widespread adoption of SAF to substantially reduce the sector’s carbon footprint. This initiative signals a clear commitment to sustainable development and a future where economic growth in aviation does not come at the expense of environmental health.

Navigating the New Regulatory Framework

Under the new regulations, the very definition of aviation fuel has been re-categorized to accommodate the shift toward sustainability, with Jet A-1 now classified into three distinct types. The first remains conventional Jet A-1, while the second category recognizes fuel produced through co-hydroprocessing, a method that integrates renewable feedstocks into existing refinery processes. The third and most forward-looking category is conventional Jet A-1 blended with pure, unadulterated SAF. To ensure quality and safety, all SAF produced within Thailand must rigorously adhere to the globally recognized ASTM D7566 norms, a standard that governs the production and properties of synthetic aviation fuels. Initially, the policy exclusively sanctions the use of Hydroprocessed Esters and Fatty Acids (HEFA) technology for SAF production. This specific focus stems from a pragmatic assessment of the current technological landscape, as HEFA is considered commercially mature and readily deployable, unlike other pathways such as Alcohol-to-Jet, which are still in developmental stages and not yet viable for large-scale commercial application.

Domestic Production Rises to the Challenge

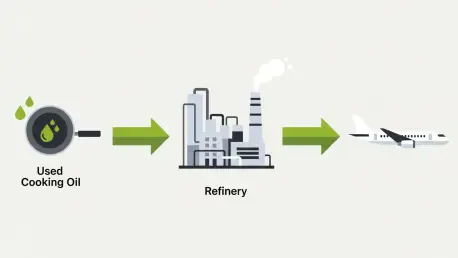

The successful implementation of this mandate was critically dependent on the nation’s capacity to develop a robust domestic supply chain, a challenge that was met with significant industrial investment. The groundwork laid by major corporations was instrumental in ensuring a steady supply of locally produced SAF from the outset. Bangchak Corporation’s development of a large-scale HEFA plant represented a cornerstone of this strategy. Designed to utilize used cooking oil as its primary feedstock, the facility’s projected output of one million liters per day, which was scheduled to come online in the second quarter of 2026, was a clear signal of the country’s commitment. Furthermore, PTT Global Chemical had already entered commercial operation, producing SAF from the same feedstock via a co-processing HEFA method. Though its initial capacity was a more modest 16,000 liters per day, its operational status provided immediate supply and valuable experience. These pioneering projects did not just fulfill a regulatory requirement; they established a new, circular economy for waste materials and positioned Thailand as a self-reliant leader in the regional sustainable aviation fuel market.