In a landmark move to address the aviation industry’s substantial carbon footprint, a pioneering project is set to transform discarded used cooking oil into a powerful, low-emission fuel capable of powering the next generation of air travel. This initiative, led by SAF One Energy Management, signals a decisive shift away from conventional fossil fuels and toward a circular economy where waste streams become a valuable resource for one of the world’s most energy-intensive sectors. Tata Projects Limited has been selected as the exclusive engineering, procurement, and construction (EPC) partner for this groundbreaking sustainable aviation fuel (SAF) plant in the Middle East.

Powering the Future of Air Travel with Greener Fuel

As global aviation confronts its significant environmental impact, the development of viable alternatives to traditional jet fuel has become an urgent priority. This project directly addresses this challenge by creating a renewable fuel source from readily available waste materials. By converting used cooking oil and other waste-based oils into certified sustainable aviation fuel, the facility will provide a tangible solution to reduce the industry’s carbon emissions.

The initiative represents a pivotal moment in the transition toward greener aviation, demonstrating that sustainable alternatives are not only feasible but also scalable. It marks a critical step in building a more resilient and environmentally responsible fuel supply chain, turning a local waste problem into a global climate solution. The project’s location in the Middle East, a major crossroads for international air travel, amplifies its strategic importance.

The Strategic Imperative of Sustainable Aviation Fuel

The airline industry faces immense pressure to decarbonize its operations amid projections of continued growth in passenger and cargo traffic. Sustainable aviation fuel stands as a game-changer because it offers a “drop-in” solution, meaning it is chemically similar to conventional jet fuel and can be used in existing aircraft and infrastructure without major modifications. This compatibility removes a significant barrier to adoption and allows for a more immediate impact on emissions reduction.

Furthermore, producing SAF from waste-based feedstocks aligns with the principles of a circular economy. It diverts waste from landfills, creates economic value from discarded materials, and reduces the lifecycle carbon footprint of air travel. For a region heavily invested in both aviation and energy, this project establishes a new model for industrial innovation that supports both economic growth and environmental stewardship.

A Replicable Blueprint for Global SAF Production

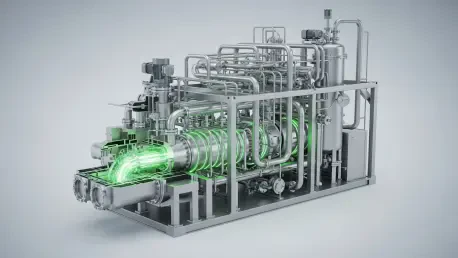

At the heart of this venture is a strategic alliance between SAF One Energy Management, the project visionary, and Tata Projects, its exclusive EPC partner. The collaboration is built on a “copy-and-paste” model designed for rapid and cost-effective global expansion. This approach utilizes a standardized plant design and modular execution, where components are fabricated off-site and assembled on-location, significantly shortening construction timelines and ensuring consistent quality.

The facility’s core technology converts waste-based oils and fats into a high-grade fuel that meets stringent international SAF certification standards. This standardized blueprint is not a one-off solution; it is the foundation of SAF One’s broader strategy to establish a worldwide network of SAF production facilities. Demonstrating this global ambition, a similar plant is already under consideration for development in India, a rapidly expanding aviation market.

Forging a Partnership on Expertise and Vision

The selection of Tata Projects underscores the critical importance of proven engineering and construction expertise in bringing this ambitious vision to life. The company brings an extensive track-o-record of delivering complex, fixed-price turnkey projects in the energy sector, providing the reliability and predictability necessary for such a pioneering endeavor. This experience is essential for managing the intricate logistics and technical demands of building a state-of-the-art biorefinery.

Leadership at SAF One has expressed confidence in Tata Projects’ capabilities, particularly its unwavering focus on safety, its mastery of standardized execution, and its ability to deliver on a common global design. This shared commitment to excellence and innovation forms the foundation of a powerful partnership. The collaboration reinforces both companies’ positions as key players in the global energy transition and their dedication to developing the future-ready fuel infrastructure needed to support a decarbonized world.

A Strategic Framework to Replicate Success Globally

The long-term success of this initiative hinges on a meticulously planned four-step strategic framework designed for efficient replication. The first step involves cementing the standardized design, creating a universal and repeatable plant model that ensures operational consistency and efficiency across all future locations. This foundational blueprint minimizes the need for redesign and streamlines the procurement process for subsequent facilities.

Following the design phase, the framework emphasizes modular construction, leveraging modern, off-site fabrication techniques to control costs and accelerate project timelines. The third pillar is flexible feedstock integration, which ensures each facility is engineered to process a diverse range of waste materials, thereby creating a resilient and adaptable supply chain. Finally, this entire model is geared for rapid deployment, allowing the established blueprint to be quickly implemented in other expanding aviation markets worldwide, accelerating the global availability of sustainable aviation fuel.