The successful modernization of sugar refining facilities, exemplified by the Parag Agro Foods project, represents a significant advancement in the agro-processing sector. This review will explore the evolution of clean-tech solutions, their key features, performance metrics like steam consumption reduction, and the impact they have had on both operational efficiency and environmental sustainability. The purpose of this review is to provide a thorough understanding of these technologies, their current capabilities in a real-world setting, and their potential for future development across the industry.

Introduction to Modernization in Sugar Processing

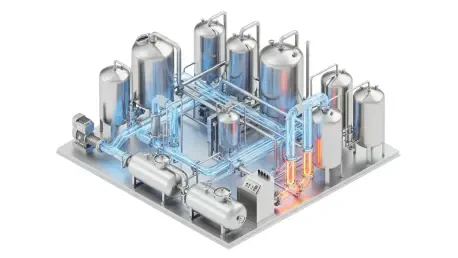

The sugar industry has historically been energy-intensive, facing persistent challenges related to high steam and power consumption. This operational model, while functional, created significant economic and environmental pressures. In response, a new generation of high-efficiency process equipment has emerged, specifically designed to optimize thermal performance and reduce the carbon footprint of refining operations.

The successful modernization project at Parag Agro, engineered by Spray Engineering Devices Limited (SED), serves as a critical case study. It highlights a pivotal shift in industry philosophy, moving away from traditional capacity expansion toward a more integrated approach. This new paradigm prioritizes both production volume and the establishment of sustainable, cost-effective operations for long-term viability.

Analysis of Key Technological Upgrades

Advanced Evaporation Systems for Steam Economy

Falling Film Evaporators (FFEs) are central to modernizing the evaporation stage of sugar refining. By creating a thin, uniform film of juice that flows downward under gravity, these systems achieve superior heat transfer coefficients compared to traditional evaporators. This efficiency means less energy is required to achieve the same level of evaporation. The Parag Agro plant’s installation of four 5,000-square-meter FFEs significantly improved its steam economy, forming the foundational element of its landmark reduction in steam consumption from a high of 32% down to approximately 22% on cane.

High-Efficiency Crystallization Technologies

The Spray Continuous Pan (SCP) system revolutionizes the crystallization process by enabling stable, low-temperature operations, which were previously difficult to maintain. A critical feature of this technology is its ability to run on low-grade vapors drawn directly from the evaporators rather than requiring high-pressure prime steam. This design not only yields substantial direct energy savings but also allows for meticulously controlled crystal growth. Consequently, this leads to improved sugar quality and consistency, a key metric for market competitiveness. The addition of three SCP chambers was a key element in Parag Agro’s efficiency gains.

Integrated Heat Recovery and Process Automation

Maximizing energy efficiency requires a holistic approach that extends beyond individual pieces of equipment. The project incorporated dedicated condensate heaters to recover and reuse latent heat from raw and sulphited juice, effectively minimizing thermal losses that would otherwise be wasted. Furthermore, the complete integration of all new equipment into the plant’s Distributed Control System (DCS) was crucial for success. This level of automation facilitates real-time monitoring and precise control over all process parameters, ensuring sustained operational stability and peak performance throughout the entire crushing season.

Emerging Trends in Sustainable Industrial Growth

The Parag Agro project exemplifies a major trend in the processing industry: viewing sustainability and productivity as interconnected goals rather than competing priorities. Companies are increasingly investing in clean-tech solutions that deliver a dual return on investment through lower operating costs and a reduced environmental impact. This shift signals a maturation of the industrial sector, where long-term profitability is directly linked to responsible resource management.

The move toward comprehensive automation via DCS integration also reflects a broader shift toward data-driven manufacturing. In this model, process optimization is not a one-time event but a continuous cycle informed by real-time analytics. This allows operators to make subtle adjustments that collectively yield significant gains in efficiency and output over time.

A Case Study in Application: The Parag Agro Plant Modernization

The comprehensive, two-phase upgrade of the Parag Agro facility in Ravadewadi, Pune, serves as a benchmark for the sugar industry. The primary achievement was the successful expansion of its processing capacity to 7,000 tonnes of cane per day (TCD) while simultaneously achieving a landmark reduction in energy consumption. The project, from engineering to commissioning by SED, demonstrates a practical and replicable model for modernizing existing plants to meet higher production targets with enhanced cost-efficiency and improved environmental performance.

Challenges and Strategic Solutions in Implementation

Retrofitting an operational plant with advanced technology presents significant challenges, including ensuring seamless integration with existing infrastructure and maintaining production stability during the transition. Any disruption can lead to costly downtime, making the implementation phase critical. Parag Agro and SED mitigated these risks through a carefully planned, phased implementation strategy that minimized operational interruptions.

The technical challenge of synchronizing multiple new high-efficiency units was addressed by leveraging a robust and centralized DCS. This system provided the necessary control and oversight to manage the newly complex and highly optimized processes. The DCS acted as the digital backbone of the modernization, ensuring all components worked in concert to achieve the desired efficiency targets.

Future Outlook for Sustainable Sugar Manufacturing

The success of the Parag Agro modernization provides a clear blueprint for the future of sugar refining. The industry is poised for wider adoption of integrated energy-saving technologies like FFEs, SCPs, and advanced heat recovery systems as they become the new standard for competitiveness. Future developments will likely focus on even deeper integration with co-generation facilities, the use of artificial intelligence for predictive process control, and a greater emphasis on water conservation. In the long term, these advancements will be critical for the industry to remain profitable and environmentally responsible.

Conclusion: Setting a New Industry Standard

The modernization of the Parag Agro sugar plant was a definitive success story, demonstrating that significant capacity expansion can be achieved in tandem with major improvements in energy efficiency. The strategic implementation of advanced technologies resulted in a substantial reduction in steam consumption, which translated directly to lower operating costs and a smaller carbon footprint. This review confirms that such integrated clean-tech solutions are not just viable but essential for the future of the industry, establishing a new performance benchmark for sustainable and profitable sugar refining.