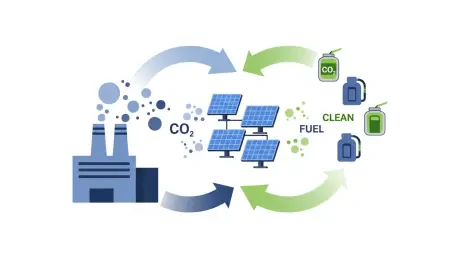

With a deep background in energy management and grid security, Christopher Hailstone offers a unique perspective on the technologies poised to redefine our energy landscape. Today, we’re diving into a groundbreaking development that sounds like science fiction: using solar energy to transform harmful CO₂ into valuable renewable fuels, a critical innovation as atmospheric carbon levels continue to rise.

This new photo-electrochemical method seems to be a significant leap beyond earlier attempts at CO₂ conversion. Could you explain what makes this hybrid approach so much more effective and how that translates to tangible improvements in the lab?

Absolutely. What we’re seeing is the power of integration. Think of it as combining the best of two worlds: photocatalysis, which uses light, and electrocatalysis, which uses an electrical current. By merging them, we solve a major bottleneck of older systems. The external electrical support drastically improves the separation of electric charges generated by sunlight, which is the engine of the entire reaction. This enhanced efficiency also allows us to cleanly separate the fuel products as they’re made, which is a huge advantage because it eliminates the need for expensive and complex purification steps later on.

The research highlights a sophisticated cocktail of materials, from titanium dioxide and copper oxides to graphene and even nanoparticles of gold and silver. How do all these distinct components function as a unified system to drive this conversion process?

It’s a fantastic example of materials science synergy, where each part plays a specialized role. The metal oxides like titanium dioxide form the fundamental semiconductor structure that captures sunlight. However, they’re often not efficient on their own. That’s where the metal nanoparticles, like gold and silver, come in. They act as antennas, dramatically improving light absorption, especially in the visible spectrum, and they help prevent energy from being lost as heat. Then you have graphene-based materials layered in, which serve as superhighways for the electric charges to move efficiently and provide a massive surface area for the CO₂ molecules to attach to and react.

Given that atmospheric CO₂ has surpassed 420 parts per million, the pressure is on to scale up solutions like this. What are the primary technical and economic hurdles we need to overcome to move this from the lab to large-scale industrial use?

That’s the critical question. While the science is promising, scaling is a major challenge. We need to ensure these complex nanomaterials can be manufactured reliably and durably on a massive scale without losing their high performance. The biggest economic hurdle is cost. Right now, producing fuels like methanol or syngas this way is still more expensive than traditional fossil fuel methods. However, the path to cost-competitiveness is becoming clearer. As the cost of renewable electricity continues to plummet, the economics of powering these electrochemical systems become far more attractive, which is essential for making this a viable industrial process.

The concept of an “artificial leaf” that mimics photosynthesis is incredibly compelling. Could you elaborate on how this engineered system is designed to outperform a natural leaf and what key innovations are still needed to make these devices a common reality?

The artificial leaf is the ultimate goal here. It’s about taking the brilliant concept of photosynthesis and engineering it to be far more efficient and controllable than nature ever intended. A natural leaf is incredible, but it’s not optimized for fuel production. Our artificial systems can be designed with materials that absorb a wider spectrum of light and convert that energy into chemical bonds with much higher efficiency. We can also precisely control the chemical pathways to produce specific high-value fuels like ethanol or formic acid, rather than just sugars. The key breakthroughs needed now are in system integration—creating stable, self-contained devices that can operate for years in real-world conditions with minimal maintenance.

What is your forecast for solar-powered CO₂ conversion technology?

I am incredibly optimistic. This technology represents one of the most promising pathways for creating a truly circular carbon economy. As we continue to refine the materials and drive down the cost with cheaper renewable electricity, I foresee a future where industrial facilities can capture their own CO₂ emissions and convert them on-site into valuable chemicals and fuels. It’s not a question of if this technology will become competitive, but when. Within the next decade, I believe we’ll see pilot plants demonstrating economic viability, paving the way for a major shift in how we manage carbon and produce energy.