The global pursuit of decarbonization has often grappled with the immense challenge posed by heavy industries, where carbon-intensive processes are deeply embedded in production, and aluminum smelting stands out as one of the most energy-demanding manufacturing processes on the planet. This reality has long positioned the lightweight, versatile metal as a significant contributor to global emissions. However, a landmark strategic collaboration is now charting a new course, seeking to fundamentally reshape the industry’s environmental footprint. Indian energy transition platform AM Green and Japanese global trading firm Mitsui & Co., Ltd., have formalized a Memorandum of Understanding (MoU) that could pioneer the world’s first large-scale, vertically integrated green aluminum production ecosystem. This ambitious venture moves beyond incremental improvements, proposing a systemic overhaul powered entirely by renewable energy, potentially creating a blueprint for decarbonizing one of the world’s most critical and hard-to-abate sectors. The partnership signals a powerful convergence of green energy development, industrial manufacturing, and global finance.

The Blueprint for a Sustainable Smelter

A Vertically Integrated Vision

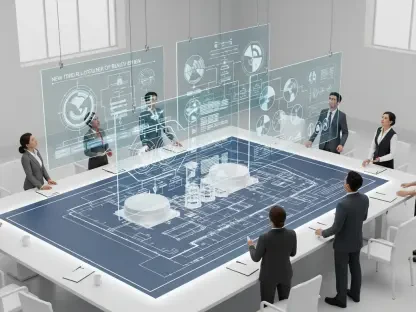

At the heart of this initiative lies an ambitious project spearheaded by AM Green’s subsidiary, AM Green Metals, located in Andhra Pradesh, India. The plan encompasses the development of a comprehensive industrial complex designed for sustainability from the ground up. This includes a state-of-the-art primary aluminum smelter with a projected capacity of one million tonnes per annum (MTPA), which will be directly supported by a two MTPA alumina refining facility and associated mining operations. The strategic decision to vertically integrate these components is crucial, as it provides end-to-end control over the production chain. This integration minimizes logistical complexities, reduces transportation-related emissions, and ensures that every stage of the process, from raw material extraction to final metal production, adheres to stringent environmental standards. By consolidating operations, the project aims to create a closed-loop system that optimizes efficiency and resource management, setting a new global benchmark for how industrial metals can be produced at scale without relying on traditional, fossil fuel-based energy infrastructure.

The Renewable Power Backbone

The single most critical element that distinguishes this project is its unwavering commitment to being powered exclusively by renewable energy, a radical departure from the coal-dependent grids that fuel most of the world’s existing smelters. To achieve this, the entire complex will be energized by a dedicated and massive renewable power infrastructure. This supply, secured through a separate MoU with Coal India, will deliver 4.5 GW of clean energy, a scale sufficient to power the entire operation. The energy portfolio will feature a sophisticated mix of wind and solar power generation, ensuring a consistent output that capitalizes on varying weather conditions. More importantly, this variable generation will be stabilized by a large-scale pumped hydro storage system. This storage solution is vital for providing reliable, round-the-clock power, which is an absolute necessity for the continuous and energy-intensive aluminum smelting process. This innovative energy architecture not only eliminates the project’s reliance on the carbon-intensive grid but also addresses the core challenge of intermittency that often limits the industrial application of renewables.

Forging a Global Alliance

Strategic Capital and Market Access

The partnership with Mitsui & Co. is positioned as a pivotal catalyst, transforming this ambitious vision into a commercial reality. The MoU outlines a pathway for Mitsui to make a direct investment into the AM Green Metals value chain, providing a significant injection of equity that is essential for financing a project of this magnitude. This financial backing from a global industrial and investment powerhouse lends immense credibility and stability to the venture, de-risking the substantial capital expenditure required. Beyond the crucial funding, the agreement explores powerful commercial synergies. One key aspect is the provision of offtake rights for Mitsui, which would grant the Japanese firm access to a substantial supply of the low-carbon aluminum produced. This arrangement is mutually beneficial: it secures a predictable market for AM Green’s output from the outset while allowing Mitsui to meet the soaring global demand for sustainable materials in sectors like automotive, aerospace, and consumer electronics.

Synergies in the Supply Chain

The collaboration extends deep into the operational fabric of the project, leveraging Mitsui’s extensive global network and expertise in supply chain management. The MoU considers a role for Mitsui as a key supplier of the essential auxiliary materials required to run the smelter and refinery. These inputs, which can include everything from specialized chemicals to critical components, are vital for continuous and efficient production. By integrating Mitsui into the supply chain, AM Green gains a reliable and world-class partner capable of sourcing and delivering high-quality materials, thereby enhancing operational resilience and efficiency. This multifaceted relationship transcends a simple investor-recipient dynamic, creating a deeply integrated partnership where both entities contribute core competencies. Mitsui’s involvement ensures the project is not only well-funded and has a guaranteed market but is also supported by a robust and sophisticated logistical framework, further solidifying its potential for success on the global stage.

A New Paradigm for Industrial Decarbonization

This strategic alliance between AM Green and Mitsui & Co. represented a significant inflection point in the global effort to decarbonize heavy industry. The collaboration moved beyond theoretical concepts and established a tangible, large-scale model that fused advanced renewable energy infrastructure with the industrial might required for primary metals production. The venture’s design, which integrated a dedicated, stable green energy supply with a complete production value chain, provided a compelling and commercially viable template for other hard-to-abate sectors. The partnership demonstrated how international cooperation could successfully mobilize the vast capital, market access, and supply chain expertise needed to execute such capital-intensive green projects. Ultimately, this agreement did more than just lay the groundwork for a single facility; it showcased a globally competitive platform that shifted the paradigm from ambition to execution in the complex challenge of industrial decarbonization.