Setting the Stage for a Sustainable Shift

Imagine an industrial landscape where heavy refining processes, long dependent on fossil fuels, pivot to a cleaner, greener alternative, slashing greenhouse gas emissions in one bold move. This vision is no longer a distant dream but a tangible possibility through the innovative strides made in renewable hydrogen production. Industrial refining, a cornerstone of global economies, currently relies heavily on hydrogen derived from fossil sources, contributing significantly to carbon footprints worldwide. The urgency to decarbonize such sectors has never been more critical as climate goals tighten and sustainability becomes a mandate.

The spotlight falls on a groundbreaking initiative that could redefine energy use in refining. This project, centered at a major renewable products refinery in Rotterdam, Netherlands, explores how renewable hydrogen can replace its fossil-based counterpart. By addressing this challenge, the effort not only tackles environmental impacts but also sets a precedent for other heavy industries. The significance lies in proving that sustainable alternatives are viable, potentially reshaping industrial practices on a global scale.

Exploring the MultiPLHY Project and Its Vision

The MultiPLHY project stands at the forefront of this transformation, demonstrating the production of renewable hydrogen via a high-temperature electrolyzer (HTE) at Neste’s facility in Rotterdam. This endeavor focuses on integrating cutting-edge technology into an operational industrial setting, marking a significant step toward reducing dependence on fossil-derived hydrogen. The mission is clear: to test and validate a scalable solution that could redefine energy inputs in refining processes.

Key challenges include overcoming the entrenched reliance on traditional hydrogen sources, which dominate current industrial frameworks. Questions of scalability loom large—can this technology expand to meet the vast demands of global refining? Additionally, the impact on greenhouse gas emissions remains a critical measure of success. If proven effective, this approach could offer a sustainable alternative, aligning industrial practices with environmental imperatives.

The project also prompts deeper inquiry into the broader adoption of renewable hydrogen. How will industries adapt to such a shift, and what systemic changes are needed to support widespread implementation? These considerations frame the initiative as not just a technical trial but a potential catalyst for systemic change in industrial energy use.

The Role of Renewable Hydrogen in Industrial Decarbonization

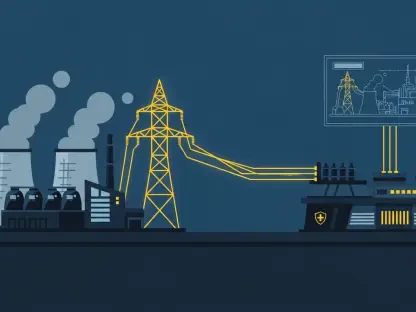

Industrial refining today depends heavily on hydrogen sourced from fossil fuels, a practice that generates substantial carbon emissions and exacerbates environmental degradation. This reliance poses a significant barrier to achieving sustainability targets, as refining processes are integral to producing fuels, chemicals, and materials essential to modern life. The environmental toll of these operations underscores the pressing need for cleaner alternatives.

Transitioning to renewable hydrogen offers a pathway to decarbonize heavy industries, aligning them with global climate objectives. Unlike its fossil-based counterpart, renewable hydrogen is produced using clean energy sources, drastically cutting emissions when integrated into industrial workflows. Its potential extends beyond refining, promising to reshape sectors like steel and chemical manufacturing, which also grapple with high carbon footprints.

The broader significance of this shift lies in its contribution to a sustainable energy future. By replacing fossil-derived inputs, renewable hydrogen could serve as a cornerstone for net-zero ambitions, supporting international efforts to combat climate change. This transition, while complex, represents a vital step toward harmonizing industrial growth with ecological stewardship.

Diving into Research Methodology, Findings, and Implications

Methodology Behind the Innovation

The MultiPLHY project thrives on a collaborative model, uniting diverse expertise from partners such as Neste, Sunfire, CEA, and ENGIE. Neste leads the integration and operation at its Rotterdam refinery, ensuring seamless alignment with existing systems. Sunfire contributes the core technology—a high-temperature electrolyzer based on Solid Oxide Electrolysis Cell (SOEC) principles—while CEA oversees project coordination, and ENGIE conducts techno-economic assessments to evaluate feasibility and cost-effectiveness.

This 2.6 MW electrolyzer, operating at 850°C, represents the world’s largest of its kind in an industrial context. The SOEC technology leverages high temperatures to enhance efficiency, a critical factor for industrial applications. A comprehensive test program is underway to validate performance metrics, ensuring the system meets the rigorous demands of real-world refining operations.

The methodology emphasizes practical deployment over theoretical modeling, focusing on real-time integration challenges and solutions. Each partner’s role is distinct yet interconnected, creating a robust framework for testing and refinement. This collaborative approach ensures that technical, operational, and economic dimensions are addressed holistically, paving the way for actionable outcomes.

Key Findings from the Project

Initial results from the MultiPLHY project highlight a major achievement: the successful startup of the multi-megawatt HTE, capable of producing over 60 kg of renewable hydrogen per hour. This milestone marks the first time such a large-scale system has been implemented in an industrial refining environment, demonstrating the feasibility of renewable hydrogen at a significant capacity.

A standout aspect of the SOEC technology is its efficiency, requiring substantially less electricity than conventional electrolysis methods. By utilizing waste heat—a resource often abundant in industrial settings—the system optimizes energy use, positioning it as an ideal solution for sectors with access to such byproducts. This efficiency could translate into lower operational costs and reduced environmental impact.

These findings underscore the technology’s readiness for practical application. The ability to produce renewable hydrogen at scale within an operational refinery signals a turning point, proving that sustainable alternatives can meet industrial demands without compromising productivity. The test program’s ongoing data collection will further refine these insights, solidifying the technology’s credibility.

Implications for Industry and Beyond

The implications of replacing fossil-based hydrogen with a renewable alternative are profound, offering a direct route to cut greenhouse gas emissions in refining. By integrating this technology, industries could significantly lower their carbon intensity, aligning with stringent regulatory frameworks and sustainability goals. This shift could ripple across other high-emission sectors, amplifying its environmental benefits.

The MultiPLHY project also serves as a blueprint for embedding renewable hydrogen into existing industrial infrastructures. Its successful deployment at Neste’s facility demonstrates that such integration is not only possible but practical, providing a model for others to follow. This proof of concept could accelerate adoption, encouraging investment and policy support for similar initiatives.

Moreover, the project highlights the scalability potential of high-temperature electrolysis. If expanded, this technology could address the hydrogen needs of larger industrial complexes, further driving down emissions. The implications extend to fostering innovation in energy systems, as industries rethink traditional practices in favor of cleaner, more sustainable solutions.

Reflections and Pathways Forward

Reflecting on Challenges and Successes

Deploying a pioneering technology like high-temperature electrolysis in a real-world industrial setting presented notable challenges, from technical integration to operational alignment. Issues such as ensuring system compatibility with refinery processes and managing high-temperature operations required innovative problem-solving. The collaborative efforts of the project partners played a crucial role in overcoming these hurdles, blending expertise to address each obstacle systematically.

One area of reflection centers on the learning curve associated with such novel deployments. While the project achieved significant milestones, there remains room for optimizing the technology’s performance and efficiency. Feedback from initial operations suggests that fine-tuning system parameters could enhance outcomes, offering valuable lessons for future implementations.

Another consideration is the potential for testing in varied industrial contexts. The current focus on refining provides a strong foundation, but exploring applications in other sectors could reveal additional challenges and opportunities. This reflection underscores the importance of iterative improvement, ensuring the technology evolves to meet diverse industrial needs.

Charting Future Research and Applications

Looking ahead, future research should prioritize scaling high-temperature electrolysis to support larger industrial applications. Expanding capacity and testing in different environments will be essential to validate the technology’s versatility and robustness. From 2025 onward, efforts could focus on integrating this system with other renewable energy sources, such as solar or wind, to further enhance sustainability.

Unanswered questions about long-term economic viability and adaptability across sectors present fertile ground for exploration. How will costs evolve as the technology matures, and can it be tailored to industries with unique energy profiles? Addressing these queries will be critical to securing broader industry buy-in and policy backing for widespread adoption.

Additionally, research could delve into hybrid energy systems that combine high-temperature electrolysis with other decarbonization strategies. Such innovations could create a more resilient and flexible framework for industrial energy use, ensuring that renewable hydrogen remains a competitive and practical solution over time. These directions offer exciting prospects for advancing clean energy goals.

Envisioning a Greener Industrial Horizon

The MultiPLHY project marked a turning point in the quest for sustainable industrial practices, with its successful deployment of a 2.6 MW high-temperature electrolyzer at Neste’s Rotterdam refinery. This technological breakthrough, coupled with the superior efficiency of SOEC systems, demonstrated that renewable hydrogen could effectively replace fossil-based inputs. The collaborative spirit among partners amplified the impact, blending diverse expertise into a cohesive and impactful initiative.

As a next step, industries must prioritize investment in scaling such technologies, leveraging the MultiPLHY blueprint to adapt solutions to varied contexts. Policymakers should also consider incentives and frameworks that accelerate the transition to renewable hydrogen, ensuring economic and regulatory support aligns with innovation. These actions could cement renewable hydrogen as a linchpin of industrial decarbonization.

Beyond immediate applications, the project opened doors to reimagining energy systems holistically, encouraging cross-sector partnerships to tackle remaining barriers. By building on this momentum, stakeholders can drive a transformative shift, positioning renewable hydrogen as a cornerstone of a cleaner, more sustainable industrial future. This vision, grounded in proven results, offers a clear path forward for global sustainability efforts.