In a world grappling with the environmental legacies of industrialization, the persistent issue of acid mine drainage (AMD) represents one of the most significant and widespread challenges, with South Africa alone discharging nearly 400 million liters of this toxic byproduct from active and abandoned mines every single day. This highly acidic, metal-rich effluent contaminates rivers, seeps into groundwater, and renders soil barren, posing a severe and long-lasting threat to ecosystems and public health. The corrosive nature of AMD also damages essential infrastructure, compounding the economic burden on communities already struggling with the aftermath of mining operations. For decades, the primary approach has been containment and costly, often incomplete, treatment. However, a revolutionary breakthrough from a collaboration between Heriot-Watt University and the University of South Africa is poised to change this paradigm entirely. Researchers have developed a novel method that not only neutralizes this hazardous waste but transforms it into a high-value chemical, effectively turning a dangerous pollutant into a critical tool for water purification and demonstrating a powerful application of circular economy principles.

From Pollutant to Purifier a New Chemical Pathway

The Science Behind the Transformation

The core of this innovation is a sophisticated yet efficient chemical process designed to be both low-energy and low-carbon. The method begins by utilizing locally sourced magnesite, a common mineral, to produce magnesium oxide nanoparticles. These nanoparticles act as a crucial agent, selectively precipitating ferric iron (Fe(III)) when introduced into the acid mine drainage. This step effectively isolates one of the most problematic and abundant metals from the toxic liquid waste. Once separated, the recovered iron precipitate is reacted with hydrochloric acid in a controlled environment. This reaction converts the iron into high-purity ferric chloride, a chemical compound widely employed as a coagulant in municipal and industrial water treatment plants. The elegance of this solution lies not only in its effectiveness but also in its reliance on readily available materials, creating a sustainable cycle where a region’s own resources can be leveraged to solve one of its most pressing environmental challenges, thereby closing the loop on a historically linear and wasteful process.

The true measure of this scientific achievement lies in its proven effectiveness in real-world applications. To validate the process, the ferric chloride produced from the recycled mine waste was subjected to rigorous laboratory testing as a water purification agent. The results were nothing short of remarkable. When applied to samples of heavily contaminated river water, the recovered coagulant demonstrated exceptional performance, successfully removing over 99% of harmful pollutants. This included a range of dangerous heavy metals such as aluminum, iron, and chromium, which are common byproducts of mining and industrial activities. The level of purification achieved was so comprehensive that the treated water met South Africa’s stringent national standards for safe drinking water. This success confirms the high purity and commercial-grade quality of the synthesized ferric chloride, validating the entire process as a practical and highly efficient method for generating a valuable product from what was once considered intractable toxic waste.

Redefining Waste as a Resource

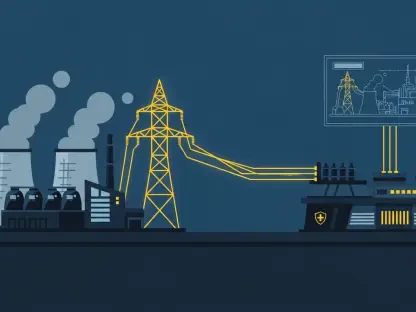

This breakthrough fundamentally reframes the global conversation around industrial byproducts, shifting the prevailing perspective from costly disposal to valuable resource recovery. Professor Vhahangwele Masindi of the University of South Africa aptly characterized this novel approach as treating wastewater streams as a “secondary mine,” a rich source from which valuable minerals can be systematically extracted and repurposed. This concept is the cornerstone of a circular economy, an industrial model where the outputs of one process become the essential inputs for another, thereby designing out waste and creating continuous economic value. Instead of sinking vast financial resources into the perpetual containment and remediation of toxic sites, this technology offers a clear pathway to generate ferric chloride, a commercially viable product with a robust and established market. This innovative model creates a powerful economic incentive for mining companies and governments to proactively address legacy pollution, transforming an enduring environmental and financial liability into a sustainable and potentially profitable enterprise.

Beyond the compelling economic case, the far-reaching environmental and social benefits of this technology are profound. Dr. Spyros Foteinis of Heriot-Watt University emphasized that this low-carbon solution provides a practical and accessible way to clean up contaminated mine water, directly benefiting the health and well-being of communities that have borne the brunt of mining pollution for generations. By purifying local water sources, the process can help restore damaged ecosystems, improve the viability of agriculture in affected areas, and significantly reduce the public health risks associated with chronic exposure to heavy metals and acidic water. For countless communities worldwide living in the shadow of active or abandoned mines, this innovation represents a tangible step toward environmental justice and a healthier future. It offers a sustainable model for remediation that not only removes a persistent environmental threat but also empowers communities by providing them with the means to reclaim and protect their most vital natural resource: clean water.

A Scalable Solution for a Global Challenge

From Laboratory to Community Implementation

With the process now scientifically validated, the research team is shifting its focus toward real-world application and deployment. The immediate next phase of the project involves launching pilot programs to implement the technology directly within affected rural and peri-urban communities in South Africa. The plan also includes extending these trials to other water-scarce regions where the dual problems of mining pollution and limited access to clean water are most acute. These pilot studies will be instrumental in refining the process under diverse field conditions and demonstrating its practical viability and robustness on a larger community scale. The researchers are confident that the method is fully scalable to an industrial level, offering a sustainable and cost-effective alternative for nations across the globe that are grappling with the toxic legacy of mining. By providing a clear and economically attractive pathway from waste to wealth, the technology presents a compelling business case for both private industry and public utilities to invest in large-scale environmental cleanup.

This innovation arrives at a critical moment, as the global community faces mounting pressure on its finite freshwater resources. The challenges of water scarcity are being severely exacerbated by the impacts of climate change, which is altering precipitation patterns and increasing the frequency and intensity of droughts in many parts of the world. In this context, solutions that can both restore contaminated water sources and create new avenues for water purification are more valuable than ever. While not a singular panacea, this technology represents a vital component in a larger, diversified portfolio of solutions needed to build global water resilience. Its significance was formally recognized with its presentation at the prestigious International Mine Water Association (IMWA) 2025 conference, signaling its importance to the international scientific and engineering community. It stands as a powerful example of how targeted scientific research can address complex, interconnected global challenges by creating systems that are both environmentally restorative and economically sustainable.

Charting a Course for a Cleaner Future

The development of this transformative technology marked a significant turning point in the management of industrial waste. By successfully converting toxic acid mine drainage into a high-purity water coagulant, the researchers provided more than just a solution to a specific environmental problem; they delivered a powerful and practical blueprint for the application of circular economy principles. This achievement demonstrated that legacy pollution sites could be reimagined as valuable resource hubs, challenging the long-held notion that environmental remediation and economic prosperity were mutually exclusive goals. The project’s success established a new benchmark for sustainable innovation, proving that it was possible to tackle some of the world’s most persistent environmental threats while simultaneously addressing critical resource needs, such as the global demand for clean water. It ultimately offered a clear and compelling vision for a future where industries could not only mitigate their environmental impact but actively contribute to ecological restoration.