Imagine a world where one of the mining industry’s most notorious environmental villains—acid mine drainage (AMD)—could be transformed into a hero for clean water access. This toxic byproduct, known for contaminating rivers and soil with heavy metals and extreme acidity, has long been a scourge on ecosystems and communities near mining sites. Yet, groundbreaking research from experts at Heriot-Watt University in the UK and the University of South Africa suggests a startling possibility: turning this hazardous waste into a vital water treatment chemical. This innovation promises not just to neutralize a pressing problem, but to create something valuable from it. By exploring how AMD can be repurposed into ferric chloride, a coagulant used to purify drinking water, this discovery opens up a conversation about sustainability and resourcefulness in addressing global water challenges. Could this be a turning point for mining regions struggling with pollution?

Turning Waste into a Resource

The challenge of AMD is staggering, particularly in mining-heavy regions like South Africa, where nearly 400 million liters of this acidic, metal-laden water are discharged daily from both active and abandoned coal and gold mines. This runoff doesn’t just harm the environment; it corrodes infrastructure and poses serious health risks by tainting groundwater and rivers with toxins like aluminum and chromium. However, researchers have developed a method to extract ferric iron from AMD using magnesium oxide nanoparticles sourced from local magnesite. Through a chemical reaction with hydrochloric acid, this iron is converted into ferric chloride, a powerful agent for water purification. Lab tests have shown astounding results, with the resulting chemical removing over 99% of pollutants from river water, meeting stringent drinking water standards. This approach isn’t just about cleanup; it’s about reimagining waste as a secondary resource for communities desperate for safe water.

Beyond the technical success, this innovation speaks to a broader shift toward a circular economy, where waste is no longer the end of the story but the start of a new one. The environmental burden of AMD has historically been a dead end—costly to manage and devastating to ecosystems. Now, envision a scenario where mining companies, instead of merely containing the problem, contribute to solving water scarcity issues. This method, as highlighted by the research team, requires low energy and emits minimal carbon, making it a practical fit for regions with limited resources. Professor Vhahangwele Masindi has emphasized the potential of AMD as a source of valuable minerals, while Dr. Spyros Foteinis underscores the eco-friendly nature of the process. Together, their insights paint a picture of an industry that could pivot from being a polluter to a provider of solutions, especially in areas hit hardest by mining legacies.

A Path to Global Impact

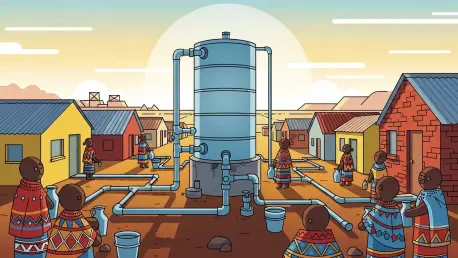

Scaling up this technology represents the next frontier, and the researchers are already laying the groundwork for real-world impact. Plans are in motion to pilot this method in rural and peri-urban communities in South Africa, where access to clean water remains a daily struggle. The vision extends far beyond one country, though. Mining pollution is a global issue, affecting countless regions with abandoned sites leaching toxins into the environment. Adapting this process to industrial levels could offer a lifeline to nations grappling with similar challenges. Moreover, the team is exploring complementary techniques to recover nutrients and clean water from municipal wastewater, suggesting a broader strategy to tackle interconnected water issues. If successful on a larger scale, this could redefine how industries and governments approach environmental liabilities, turning them into opportunities for sustainable development.

Perhaps the most compelling aspect of this research is its alignment with urgent global needs, like combating water scarcity amid climate change pressures. As Mamile Belina Mahlohla from the team pointed out, innovations like this are critical in a world where droughts and contamination increasingly threaten water supplies. The ability to transform a destructive byproduct into a tool for purification could be a game-changer, especially for marginalized communities near mining sites who bear the brunt of pollution. While challenges remain—such as ensuring cost-effectiveness and navigating regulatory hurdles—the optimism surrounding this method is palpable. It’s not just about technical feasibility; it’s about crafting a narrative of hope for regions long burdened by the aftermath of resource extraction. This technology stands as a testament to human ingenuity, proving that even the most daunting problems can yield unexpected solutions.

Building a Sustainable Legacy

Looking back, the journey of this research marked a pivotal moment when science turned a persistent environmental threat into a beacon of possibility. The successful conversion of acid mine drainage into ferric chloride demonstrated that innovation could bridge the gap between industrial fallout and community benefit. What started as a lab experiment evolved into a powerful statement on sustainability, showing how mining waste could purify the very water it once poisoned. The dedication of the research team to pilot this in vulnerable areas reflected a commitment to tangible change over mere academic achievement.

Moving forward, the focus must shift to actionable steps: securing funding for broader implementation, forging partnerships with mining industries, and refining the process for diverse regional needs. Governments and stakeholders should prioritize integrating such technologies into environmental policies, ensuring that the legacy of mining isn’t just pollution, but progress. This breakthrough challenged the status quo, and now the task is to carry that momentum into a future where clean water is no longer a distant dream for millions.