The North American solar market represents a massive opportunity, valued at over $35 billion, yet it is protected by a complex web of regulations and standards that can be impenetrable for unprepared manufacturers. For any company producing solar inverters and dreaming of tapping into this lucrative landscape, one designation stands above all others as a non-negotiable gatekeeper: UL1741. This standard, developed by Underwriters Laboratories, is far more than a simple safety recommendation; it is the essential passport required for grid access, consumer acceptance, and eligibility for critical government incentives. Without it, even the most technologically advanced inverter is effectively barred from entry, unable to connect to the utility grid or qualify for the financial programs that drive the industry’s growth. Understanding the depth of its requirements, the tangible market impact of compliance, and the practical steps to achieve certification is paramount for any stakeholder aiming for sustainable success in the U.S. and Canada.

1. The Undeniable Mandate for Market Access

At its core, UL1741 is a comprehensive safety standard specifically designed for inverters, converters, controllers, and interconnection system equipment used with distributed energy resources like photovoltaic systems. It establishes stringent benchmarks for electrical safety, grid interoperability, and operational reliability, making it a mandatory certification for virtually all solar inverters sold or installed in the United States and Canada. The Solar Energy Industries Association (SEIA) underscores this reality, reporting that an overwhelming 98% of both utility-scale and residential PV projects across North America mandate UL1741 certification as a prerequisite for approval. This requirement is not merely a suggestion but a hard-line rule enforced by local utilities and inspection authorities. Inverters lacking this credential cannot obtain the necessary approval for grid interconnection, rendering them unusable for the vast majority of applications. Furthermore, compliance is directly tied to financial viability, as federal tax credits, such as the 30% solar investment tax credit under the Inflation Reduction Act, are contingent upon equipment meeting these established safety standards.

The standard’s authority extends beyond mere technical validation; it serves as a foundational element of trust and risk management for the entire energy ecosystem. For utility companies, UL1741 provides assurance that an interconnected device will operate predictably and safely, without destabilizing the grid or endangering personnel. For consumers, the UL mark signifies that a product has undergone rigorous third-party testing to mitigate risks of fire, electrical shock, and equipment failure. This broad-based reliance on the standard transforms it from a technical hurdle into a strategic imperative. Manufacturers who successfully navigate the certification process gain not only a product that is legally permissible for sale but also one that carries an implicit endorsement of safety and quality. In a market where reliability is paramount, this certification becomes a powerful differentiator and a key enabler of market penetration, allowing companies to build a reputation for dependability and secure a competitive foothold in a highly regulated and discerning industry.

2. Decoding The Critical Compliance Requirements

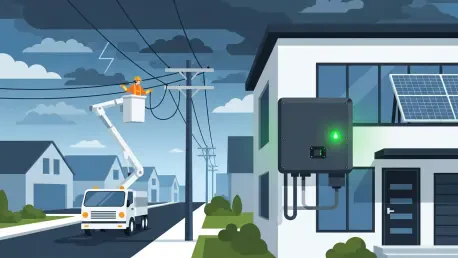

The UL1741 standard is built upon several critical pillars of performance and safety, each designed to address specific risks associated with integrating solar power into the existing electrical grid. One of the most crucial of these is anti-islanding protection. This function ensures that in the event of a grid power outage, the solar inverter will automatically cease exporting power and disconnect from the grid within a strict two-second timeframe. This rapid shutdown is vital to prevent the formation of an “island,” where a localized section of the grid remains energized by the PV system. Such a scenario poses a lethal threat to utility workers who, believing the lines are de-energized, could be exposed to unexpected electrical currents while performing repairs. Another key dimension is grid compatibility. For the common 120V/240V split-phase systems found in U.S. homes, inverters must demonstrate the ability to maintain stable operation by keeping voltage and frequency fluctuations within a tight ±5% of their nominal values, a requirement adopted from the foundational IEEE 1547 standard for interconnecting distributed resources.

Furthermore, the standard places a heavy emphasis on physical safety and durability, particularly concerning fire prevention. All components within the inverter must meet the rigorous UL 94 flammability standards, ensuring they are resistant to ignition and will not contribute to the spread of a fire. The design must also inherently prevent conditions that could lead to overheating or short circuits, which are common causes of electrical fires. The standard is not a static document; it evolves to address technological advancements and new market trends. The 6th edition, updated in 2023, introduced significant new mandates reflecting the growing integration of energy storage with solar. It now requires that hybrid inverters demonstrate compatibility with specific battery chemistries, notably Lithium Iron Phosphate (LiFePO4), which has become a dominant technology in residential energy storage. Additionally, this latest version mandates support for smart grid communication protocols like OpenADR, enabling inverters to interact with the grid intelligently and participate in demand-response programs, thus paving the way for a more resilient and interactive energy infrastructure.

3. The Tangible Impact of Certification on Business

Achieving UL1741 certification translates directly into measurable market advantages and significant financial returns, making the investment in compliance a clear business necessity. The data paints a compelling picture of its impact on market acceptance and profitability. According to research from the National Renewable Energy Laboratory (NREL), inverters bearing the UL1741 certification account for a staggering 95% of all residential PV installations in North America. This near-total market saturation illustrates that, from a practical standpoint, the certification is the price of admission. Without it, a product is relegated to a niche, off-grid market that represents only a tiny fraction of the overall industry. This reality is reinforced by consumer behavior; a survey conducted by Consumer Reports revealed that 82% of U.S. solar buyers actively prioritize UL-certified components in their purchasing decisions. This preference is driven by the understanding that certification significantly reduces the risk of fire and electrical failure, with data suggesting a 70% lower incidence of such issues in certified equipment, fostering a level of trust that is invaluable.

The financial implications of non-compliance are equally stark, extending beyond lost sales to include direct punitive costs. Products that fail to meet the standard face significant regulatory hurdles. According to data from the U.S. Consumer Product Safety Commission, non-compliant electrical equipment often triggers import alerts, and shipments can be subjected to an average fine of $15,000 per incident. These penalties, combined with the costs of reworking or recalling products, can quickly erode a manufacturer’s profitability and damage its reputation. Conversely, certified inverters avoid these pitfalls and unlock opportunities for higher revenue and wider distribution. By meeting the standard, manufacturers ensure their products are eligible for a vast array of projects, can be easily stocked by distributors, and are readily approved by installers and inspectors. In this context, UL1741 compliance is not merely an operational task but a cornerstone of a sound business strategy, directly influencing project eligibility, consumer trust, and long-term financial health.

4. A Strategic Imperative Beyond Compliance

The path to UL1741 certification, while rigorous, was a well-defined process that successful manufacturers integrated into their product development lifecycle. The journey began with pre-certification testing, where manufacturers engaged with UL-recognized third-party laboratories to conduct a comprehensive evaluation of their inverter’s performance against the standard’s criteria. This phase meticulously verified critical functions like anti-islanding response times, grid compatibility under various load conditions, and overall electrical and fire safety performance. Following successful testing, the next step involved the meticulous preparation and submission of extensive documentation to UL for review. This package typically included detailed technical specifications, a complete list of all internal components, and the official test reports from the accredited lab. On average, this review and certification cycle took between three and six months to complete, a timeline that required careful planning to align with market entry strategies.

However, earning the certification marked the beginning, not the end, of the compliance obligation. Maintaining the UL1741 credential required an ongoing commitment to quality and consistency through post-certification maintenance. This program included regular follow-up inspections by UL, often in the form of quarterly factory audits, to ensure that the production processes and components continued to adhere to the standards under which the product was originally certified. Any subsequent design changes or component substitutions necessitated a re-evaluation and an update to the certification file to ensure continued compliance. For the growing segment of hybrid inverters designed for energy storage integration, the process involved additional testing under the UL1741 Supplement Attachment (SA) to validate their safe and effective operation with battery systems. This comprehensive, end-to-end process demonstrated that compliance was not a one-time event but a sustained commitment that ultimately built a foundation for enduring success in the North American solar market.