As the global demand for clean, sustainable energy continues to surge, the world faces a pressing challenge: finding a reliable and abundant fuel source to power the future. Nuclear fusion, often hailed as the holy grail of energy production, promises limitless power with minimal environmental impact, but it comes with a significant hurdle—securing a steady supply of tritium, a rare hydrogen isotope essential for fusion reactions. Japan, a leader in technological innovation, is stepping up to address this critical issue through the pioneering efforts of Kyoto Fusioneering, a company at the forefront of fusion energy research. Their groundbreaking approach to tritium recovery and fuel cycle management could potentially transform the landscape of energy production. This article delves into the intricacies of their technology, the challenges of fuel supply in fusion energy, and the broader implications of their work for achieving a sustainable energy future on a global scale.

Tackling Tritium Scarcity with Innovative Technology

The scarcity of tritium in nature poses one of the most formidable barriers to commercial fusion power, as this isotope must be artificially produced, or “bred,” within reactors to sustain operations. Kyoto Fusioneering has developed a cutting-edge solution known as the Vacuum Sieve Tray (VST) system, currently under rigorous testing at their UNITY-1 facility. This proprietary technology disperses a tritium-rich liquid lithium-lead alloy into fine droplets within a vacuum chamber, vastly increasing the surface area for efficient extraction of the trapped tritium gas. Initial experiments utilize deuterium and hydrogen as substitutes to validate the recovery process, setting a strong foundation for future tests with actual tritium. The precision and efficiency of this method mark a significant departure from traditional approaches, offering a glimpse into how fusion reactors might one day operate self-sufficiently without relying on scarce external fuel sources, thereby addressing a critical bottleneck in the path to scalable energy production.

Beyond the VST system, the broader vision of Kyoto Fusioneering encompasses a comprehensive strategy to manage the entire fuel supply chain through their Fusion Fuel Cycle System. This integrated framework not only focuses on breeding and recovering tritium but also on storing and reintroducing it into the reactor for continuous operation. The importance of such a system cannot be overstated, as a reliable fuel cycle is essential for the economic and practical viability of fusion power plants. Satoshi Konishi, Co-Founder & CEO of the company, has emphasized that demonstrating effective hydrogen recovery builds crucial confidence among industrial partners, paving the way for commercial applications. This holistic approach distinguishes their efforts from isolated technological advancements, highlighting a commitment to solving systemic challenges in fusion energy and ensuring that the infrastructure for fuel management evolves alongside reactor technology.

Bridging Theory and Practice with Global Collaboration

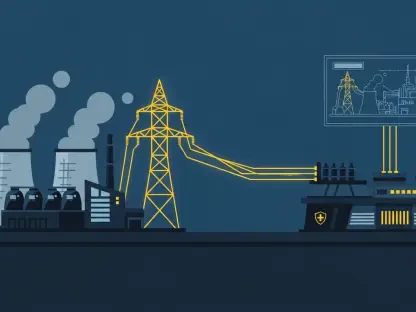

A notable trend in fusion energy research is the shift from theoretical models to tangible, real-world applications, and Kyoto Fusioneering is leading this transition with ambitious projects that extend beyond national borders. One such endeavor is the upcoming UNITY-2 facility in Ontario, Canada, a collaborative venture with Canadian Nuclear Laboratories. Known formally as the Unique Integrated Testing Facility, UNITY-2 is under construction at Chalk River Laboratories and aims to be the world’s first to demonstrate a complete, full-loop tritium fuel cycle under fusion-relevant conditions. This facility will test critical components such as fuel injection, exhaust management, impurity removal, isotope separation, and tritium storage, with the capacity to circulate significant quantities of tritium daily. The international scope of this project underscores the global stakes of fusion energy and the collaborative effort required to turn laboratory concepts into operational systems.

The significance of UNITY-2 extends beyond mere technical validation; it represents a pivotal step toward commercial viability by simulating real-world fusion conditions in a controlled environment. The facility’s ability to handle complex processes like isotope separation and impurity management addresses practical challenges that have long hindered the scalability of fusion power. By integrating these elements into a cohesive testing framework, the project provides invaluable data that can inform the design of future commercial reactors. This move from isolated experiments to a fully integrated system highlights a maturing field where innovation meets application. Moreover, the partnership with Canadian expertise illustrates how cross-border collaboration can accelerate progress, pooling resources and knowledge to tackle the multifaceted challenges of fusion fuel supply and reactor operation on an unprecedented scale.

Paving the Way for a Sustainable Energy Legacy

Reflecting on the strides made by Kyoto Fusioneering, it’s evident that their efforts have carved a promising path toward resolving the fuel supply challenges that once seemed insurmountable in fusion energy. The successful testing of the Vacuum Sieve Tray technology at UNITY-1 and the groundbreaking construction of UNITY-2 stand as testaments to a relentless pursuit of innovation grounded in practical outcomes. These milestones not only validate critical components of the fuel cycle but also foster trust among stakeholders that fusion could become a cornerstone of global energy solutions. Looking ahead, the focus must shift to scaling these technologies, securing regulatory approvals, and fostering further international partnerships to deploy fusion power plants worldwide. Continued investment in research and infrastructure will be vital to refine these systems, ensuring they meet the rigorous demands of commercial energy production while maintaining safety and sustainability as core priorities.