With me today is Christopher Hailstone, a renowned utilities expert whose career has been dedicated to analyzing the complex interplay of energy management, grid security, and large-scale industrial development. We’re here to dissect the monumental expansion plans of the Dangote Group, sparked by a recent $400 million equipment deal that signals a dramatic acceleration in its strategy. Our conversation will explore the tangible impact of this new machinery on project timelines, the market logic driving their massive push into petrochemicals and fertilizers, and how this Nigerian behemoth is poised to redraw the energy and industrial map of Africa. We’ll also touch on the broader economic implications for the region and the ambitious financial targets the company has set for itself.

Regarding the $400 million equipment deal with XCMG, what specific types of heavy-duty machinery are being acquired? Could you detail how this new equipment will practically accelerate the refinery’s build-out to meet the three-year completion target?

This $400 million infusion of capital equipment is fundamentally about brute force and efficiency. We are talking about a broad range of heavy-duty machinery—think massive mobile cranes, excavators, earthmovers, and specialized transport vehicles. These are the workhorses of any mega-project. Their immediate impact is twofold: first, they allow for parallel construction streams to operate without bottlenecks. You can be laying foundations for the petrochemical expansion while simultaneously erecting structures for the refinery’s next phase. Second, it complements the existing asset base, reducing downtime and maintenance-related delays. Having this surge capacity is critical to compressing the timeline and realistically hitting that ambitious three-year target for completion. It’s a clear signal they are moving from a steady build-out to an all-out sprint.

The expansion plans to increase polypropylene capacity to 2.4 million tons and make Dangote Africa’s biggest supplier of linear alkyl benzene. What is the market strategy behind these specific petrochemical targets, and what steps are involved in scaling production this significantly?

The strategy here is a classic case of vertical integration and import substitution on a continental scale. By scaling polypropylene from 900,000 to 2.4 million tons, they are positioning themselves to dominate the raw material supply for Africa’s growing manufacturing, packaging, and automotive industries. Similarly, becoming the continent’s biggest supplier of linear alkyl benzene at 400,000 tons annually means they will supply the essential ingredient for countless detergent and cleaning product manufacturers who currently rely on expensive imports. Scaling this requires not just building the physical plants but also securing feedstock from the refinery operations, establishing a sophisticated logistics network to move the product, and locking in long-term contracts with downstream industrial consumers across the region. It’s a calculated move to capture a higher-margin market beyond just fuel.

With the goal of tripling urea production in Nigeria to 9 million tons, what are the primary logistical and agricultural sector challenges to overcome? Please describe how this surge in output positions the conglomerate to become the world’s largest urea producer.

Tripling urea output to 9 million tons in Nigeria alone is a monumental undertaking with immense challenges. Logistically, you have to consider how to move, store, and ship that volume. It will require massive investments in rail, port infrastructure, and specialized storage facilities to prevent degradation. For the agricultural sector, the challenge shifts from supply scarcity to effective distribution. You must ensure this fertilizer reaches smallholder farmers in the hinterlands, which involves overcoming last-mile delivery hurdles and creating accessible markets. When you combine this 9 million-ton output with their existing 3 million-ton plant in Ethiopia, you’re looking at a production base that eclipses other global players. This scale gives them incredible pricing power and the ability to influence global food security dynamics, effectively making them a central bank for fertilizer.

The fully operational refinery is expected to reduce Nigeria’s dependence on imported fuel. Beyond domestic supply, how will this new capacity reshape fuel pricing and distribution dynamics across West and Central Africa? Could you provide some examples of the anticipated changes?

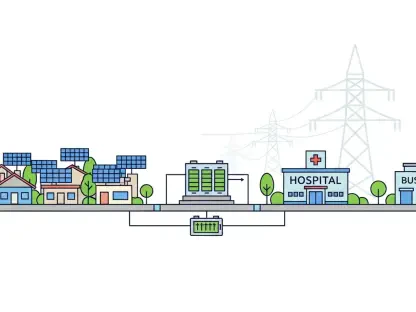

Once fully operational, the refinery becomes the dominant energy hub for an entire subcontinent. For decades, these West and Central African nations have been beholden to the volatile prices of refined fuels imported from Europe, Asia, or the Americas, which include high shipping and insurance costs. Dangote’s refinery changes that entire equation. A truck driving fuel from Lagos to a neighboring country faces a fraction of the cost and time of a tanker sailing from Rotterdam. This will lead to more stable and likely lower consumer prices at the pump across the region. We can anticipate the emergence of a more formal and efficient regional distribution network, displacing the patchwork of informal and often inefficient supply chains that currently exist. It essentially creates a new energy corridor, making the region far more self-sufficient and insulated from global supply shocks.

This equipment deal is described as a strategic investment toward becoming a $100 billion enterprise by 2030. What are the key performance indicators you are tracking, and what are the major milestones between now and then that will signal the company is on track?

The roadmap to a $100 billion valuation by 2030 is paved with very clear, tangible milestones. The primary key performance indicator, of course, is the refinery’s daily output, steadily climbing towards the full 1.4 million barrels per day target. Beyond that, we are tracking the production volumes and sales revenues from the petrochemical and fertilizer divisions. A major milestone will be the moment the polypropylene plant hits its 2.4 million-ton capacity and we see those products flowing into regional markets. Another critical signal will be when their urea exports from Nigeria begin to capture significant market share globally. Finally, achieving the status of Africa’s top linear alkyl benzene supplier isn’t just a title; it’s a verifiable market position. Each of these achievements will be a significant step-change in the company’s valuation and a clear indicator they are on track to meet that ambitious 2030 goal.

What is your forecast for the West African energy sector once the Dangote refinery reaches its full operational capacity?

My forecast is for a fundamental and irreversible shift in the region’s energy landscape. We will witness a dramatic reduction in capital flight as nations no longer need to spend billions of dollars on foreign exchange for imported fuel. This will stabilize local currencies and economies. Furthermore, the reliable, local supply of refined products will spur industrial growth, as energy will become a more predictable and manageable cost for businesses. We’ll likely see the development of ancillary industries around the refinery, from logistics and transportation to specialized maintenance services, creating a powerful economic ecosystem. The entire region will move from a position of energy vulnerability, subject to the whims of global markets, to one of greater self-sufficiency and becoming a formidable, integrated energy bloc.